We all come into contact with shrink wrap on a daily basis, be it on food packaging, DVD’s or files and folders, have you ever wondered how this process actually works? Well, we’re here to give you a simple scientific explanation on how shrink wrap actually shrinks when it comes in to contact with heat!

The whole process revolves around the manipulation of polymer molecules within the Polyolefin plastics; this is the type of plastic that our shrink wrap film is made for, specifically designed to work with out shrink wrap machinery to offer you a quality, durable and cost effective packaging solution.

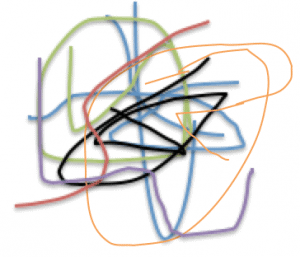

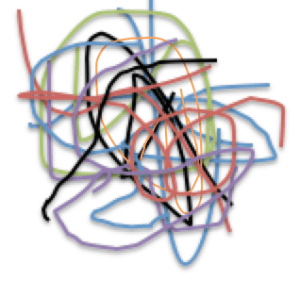

Polymer molecules in their natural state tend to be wildly tangled and intertwined, offering the characteristics of a firm and dense product that is not easily broken, as the molecules cannot untangle themselves to break apart.

When a sheet of shrink wrap plastic is first created, all the tangled molecules are laid out side by side in neat rows, this gives the smooth and even finish, allowing you to wrap the product before it enters into the shrink tunnel.

The wrap can be used on many products, from food related items, to papers, DVD’s and almost anything else you can think of! When heat is applied and the air is removed, the molecules buckle and return to their natural state, tangled together to form a strong and useful seal. This makes the product as concise as possible, ensuring that very little to no air is left within the packaging.

The tight seal created during this process means that the packaging is more tamper proof, as well as able to protect the product inside from cross-contamination, oxidising and many other dangers.

The benefits of using shrink wrap plastic as a packaging method are almost endless, from protection purposes as mentioned above, to marketing. The clear film means that you can still see the products inside and check its quality without compromising on the protection of whatever item is contained.

Image: Marco Bellucci under Creative Commons