Contact us to discuss your options and get expert advice on the best pouch packing machinery.

Pouch Filling Machinery

At Kempner, we can offer a unique range of pouch filling machinery for use with pre-made laminate pouches. Our systems are an ideal packaging solution for use in many industries, including:

- Pharmaceutical

- Chemical

- Food

- Beverage

Please contact us to discuss your requirements and we can help to determine the most suitable flow wrapping machinery for your production needs.

Get in touch

with Kempner for pouch filling machinery

Pouch Filling Machinery And Sachet Packing Machines

Constructed in stainless steel and using state of the art components, pouch filling machines are exactly suited to fill liquids, powders, granules, creams, and pastes. The very significant attributes which distinguish the range of pouch filling machinery are as follows:

- Highly competitive pricing.

- Exceptional build quality and durability, featuring a motor driven heat seal film pulling system, photo optic sensors, PLC control, touch screen control, self-diagnostics, and PID temperature control within +- 1C

- Speeds achievable of 20 – 45 ppm

- Versatility to suit a large range of pre-made pouches including stand up pouches, and those with different shapes, including screw tops, spouts and zippers etc.

- Ease of use in operation, and in changing between sizes and materials

- Ability to be interface with existing filling equipment

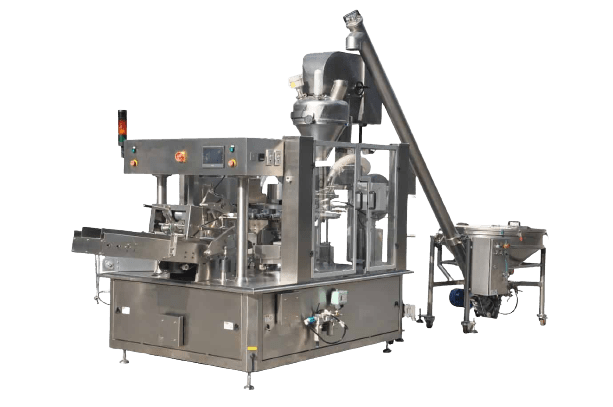

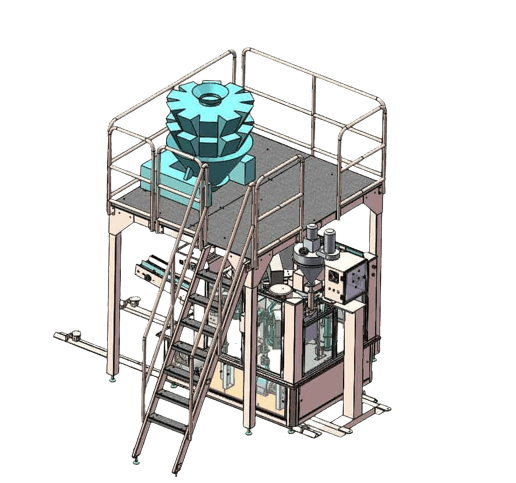

AP-8BT – 8 Station Intermittent Motion Rotary Pouch Filling Machine

The AP-8BT can be used to fill a variety of different pouches, varying in specification, size, shape and function. The pouch filling machinery interfaces both electrically and mechanically with all of the different feeding systems that are necessary for filling different types of substrates.

It utilises Auger systems for feeding fine powders such as wheat and flour, volumetric or weigh measurements for granulated products and pumping systems for liquid and paste products.

All of these options can be specified with the AP-8BT filler or the filler can be integrated into existing packaging and filling lines. Image includes filling system for powdered products.

Intermittent Rotary Machine With Advanced PLC Control System

The intermittent rotary machine has 8 stations allowing different feeds to be added to the pouch at these stations. The machine can handle a variety of different type of pre-made pouches: flat or stand up pouches, with or without zip, fitted with spouts etc. The pouch filling machinery is completely manufactured in stainless steel, suitable for the food industry, and is ideal for quick clean down when changing from one product to another.

An advanced PLC control system, combined with 5.7” colour touch screen control panel, allows fast change-over from one style and size of pouch to another, with up to 20 different sets of parameters being stored within the system. This advanced programming also shows functional data and has self-diagnostic tools.

The operation of the AP-8BT pouch filling machine is fully pneumatic which facilitates easy operation and maintenance. The unit includes a built-in vacuum system to provide suction for bag picking and opening.

Why Choose Kempner For Rotary Liquid Pouch Filling Machines?

Kempner offer the most comprehensive range of machines from stock. We have a long-standing reputation as a leading supplier of packaging machines and shrinkwrap materials in the UK. This reputation has been achieved by providing excellent value for money, combined with unsurpassable technical and customer service.

Talk to us about your packaging needs today.

Efficient and reliable packaging solutions are crucial for a wide range of businesses and operations. Pouch filling machines have gained popularity across various industries due to their adaptability, precision, and the numerous benefits they offer.

Pouching machinery can be used for food products to pet supplies, pharmaceuticals, and consumer goods, pouch filling machinery provides an optimal solution for businesses looking to streamline their product packaging processes.

Pouch filling machines are a versatile choice for the food industry. Kempner machinery can handle a wide variety of products, such as liquids, solids, and powders. Stand-up pouches, flat pouches, and spouted pouches offer airtight sealing, which helps maintain the freshness and quality of food items.

These pouch filling machines ensure accurate filling and consistent sealing for a wide variety of food products including snacks, frozen foods, sauces, powders, beverages, and more. One of the major benefits of modern pouch filling machinery is that it can reduce the risk of product spoilage and extend the shelf life of perishable goods.

In the pet industry, pouch filling machines are used for packaging pet food, treats, and supplements. Stand-up pouches with resealable closures offer convenience and airtight storage, keeping pet products fresh and protected from contaminants.

The ability to fill pouches with consistent weights and volumes ensures that customers receive the correct amount of product in every package. Pouch filling machinery can be automated to a more provide a time, energy and labour efficient way to package products on productions lines.

Accuracy, hygiene, and safety are paramount in the pharmaceutical industry. Pouch filling machinery is therefore a great option for a variety of applications. These machines can handle many different pharmaceutical products, including tablets, capsules, powders, and liquids.

Pouches offer a secure and tamper-evident packaging option, ensuring that medications are protected from environmental factors and potential tampering. This can also be beneficial for keeping products from potential sources of contamination while in transit or in storage.

From personal care products to household items, pouch filling machines cater to a broad range of consumer goods. The adaptability of pouch formats, combined with the ability to print high-quality graphics and branding on pouch films, allows businesses to create visually appealing packaging that stands out on store shelves.

Pouch filling machines also ensure that each pouch is filled accurately and consistently, maintaining product integrity and reducing waste. They can also be used with printed pouches to present products in-line with branding, as well as provide key information such as ingredients lists.

Get in touch

with Kempner now

Contact us to discuss your options and get expert advice on the best

shrink wrapping equipment and materials.