Unpacking the Potential of Post-Consumer Waste Plastic in Shrinkwrap Films

In recent years, there has been a marked shift towards sustainable practices across all industries. In the packaging sector, this has manifested as an increased focus on recycled materials, specifically post-consumer waste (PCW). PCW is a subset of recycled materials, but with a unique characteristic: it’s derived from waste products that have been discarded by consumers after fulfilling their original purpose. This is in contrast to waste generated during industrial processes or manufacturing activities.

Understanding Post-Consumer Waste (PCW)

Post-consumer waste encompasses a wide variety of items – from used paper and cardboard to discarded plastic packaging. These materials, once headed for landfills, can now find new life in the production of various goods. The goal is simple: divert waste from disposal and reintegrate it into the manufacturing cycle. The benefits are twofold: it not only mitigates the problem of waste accumulation but also reduces the reliance on virgin materials in production processes.

Post-Consumer Waste in Shrinkwrap Films

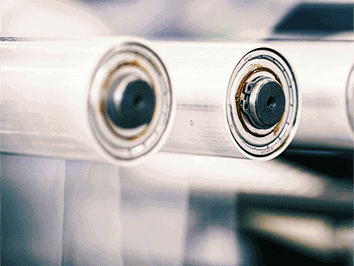

One industry that has been progressively leveraging the potential of PCW is the shrinkwrap sector. This is not surprising given that plastic, a common constituent of PCW, is the primary raw material for shrink films.

Shrink films incorporating post-consumer waste are created by following a well-defined process. First, used plastic is collected from various sources and thoroughly cleaned. The cleaning process is crucial to remove any food remnants, dirt, or other impurities that might have contaminated the plastic during its life cycle as a consumer product. After the cleaning, the plastic is processed and repurposed into new shrink films.

Incorporating PCW into shrink films represents an environmentally responsible choice. It not only decreases the volume of plastic waste heading for disposal but also curtails the production of new plastic, reducing the overall environmental footprint.

Challenges in Using Post-Consumer Waste

While the utilisation of PCW in shrinkwrap films is commendable from an environmental standpoint, it’s not devoid of challenges. One significant hurdle is the intricate and expensive process of collecting and sorting the waste. This can increase the production costs for shrink films, a factor that companies need to account for in their economic assessments.

Another concern pertains to the risk of contamination. As the plastic has been previously used by consumers, it often carries contaminants which need to be meticulously removed during the cleaning process. This additional step can further elevate the production costs.

Finally, there’s the matter of regulatory compliance. Shrink films often come in direct contact with food products, and many countries have stringent regulations in place about the use of recycled materials in food packaging. Consequently, shrink films made with post-consumer waste may not be universally suitable for all applications. Companies must ensure that their PCW-based films adhere to all applicable regional standards and regulations.

A Balanced View on PCW Shrinkwrap Films

In conclusion, while post-consumer waste brings a new dimension of sustainability to the shrinkwrap industry, it also poses unique challenges that need careful consideration. It’s a more sustainable option that reduces environmental impact, but the complexity of its processing and regulatory considerations may limit its applicability.

For businesses contemplating the use of PCW in their shrinkwrap films, it’s crucial to weigh the environmental benefits against the operational challenges and to align their choices with both their sustainability goals and business realities. As we move towards a more environmentally-conscious era, solutions like these will continue to evolve, offering us even better ways to strike a balance between commercial feasibility and environmental responsibility.